Cable Trays and Solutions Designed to Meet Stringent Hygiene Standards

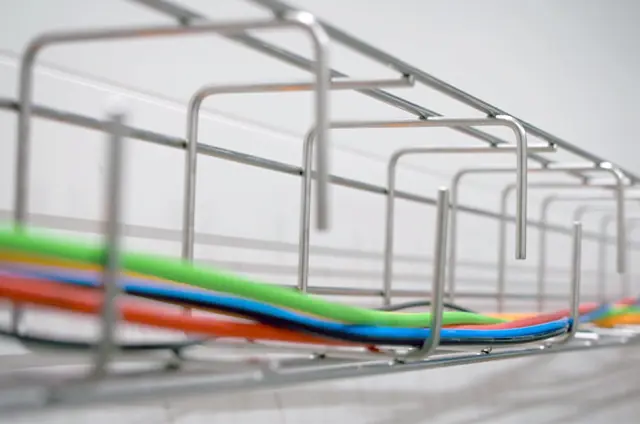

We have developed a cable management system tailored for environments with high hygiene requirements. By using wire trays and cable solutions made of stainless steel, we ensure both regulatory compliance and minimized maintenance needs.

To meet the high standards required in the food industry and other hygiene-critical environments, such as cleanrooms, we have developed an efficient cable management system in close collaboration with the industry. Our wire trays and cable solutions in 304L and 316L stainless steel help you comply with strict hygiene requirements while minimizing maintenance costs.

Key benefits for your hygienic business

1. Maximum Hygiene with Minimal Effort

Our open, smooth design minimizes surfaces where dirt and bacteria can accumulate, making it easier to maintain cleanliness in cleanrooms and production facilities. This means less time and fewer resources spent on cleaning, and greater production safety.

2. Easy to Clean and Maintain

Our cable trays are designed for easy cleaning, even with frequent use of harsh chemicals and high temperatures. This ensures you can maintain your high hygiene standards without compromising production speed.

3. Cost-Effective Installation

With a bracket spacing of up to 3 meters, you reduce the number of supports needed, simplifying installation and reducing the surfaces that require regular cleaning. This provides a more cost-effective solution over time.

4. Custom Accessories to Suit Your Needs

We offer a wide range of accessories, including Welding Brackets and Pipe Clamps, developed to facilitate easy assembly and ensure a robust installation, regardless of your production environment. These solutions are specifically designed to withstand extreme conditions, including high temperatures.

Helping you meet the stringent standards of your industry

Our cable solutions are tailored to withstand the most demanding environments in the food industry and cleanrooms. With cable trays and accessories made from 304L and 316L stainless steel, you can be confident that you’re investing in a corrosion-resistant solution that can handle harsh chemicals, ensuring a hygienic and efficient production environment.